CNC Metal Prototype Services

Bordersun CNC Metal Prototype ServicesCNC Metal Prototype Services provides various metal prototypes, including prototype of aluminum alloy, titanium alloy, copper, stainless steel or aluminum magnesium alloy and so on. Due to the hardness of metal materials, CNC machining cannot be as fast as plast......

Send Inquiry

Product Description

Bordersun CNC Metal Prototype Services

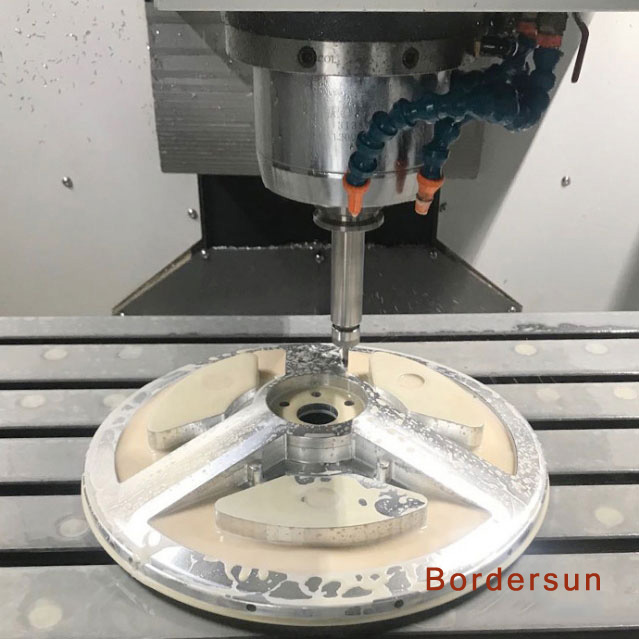

CNC Metal Prototype Services provides various metal prototypes, including prototype of aluminum alloy, titanium alloy, copper, stainless steel or aluminum magnesium alloy and so on. Due to the hardness of metal materials, CNC machining cannot be as fast as plastic prototypes. And the machining time varies according to different CNC metal prototype. Therefore, we will choose different cutter for different metal materials. With the suitable cutter, the precision of the prototype can be guaranteed.

Generally, CNC metal prototype service is used for the high value products, like laptop, digital camera and phone case. All of those have a strict requirement to the prototype in terms of appearance and dimension precision. With CNC, the basic dimension tolerance can be control between ±0.1mm, and the critical dimension tolerance can be controlled between ±0.01mm. If customers want to keep the tolerance between ±0.01mm to ±0.05mm, all they need is sending us the 2D files in the format of PDF, DWG or DXF.

Bordersun focus on CNC metal prototype service in the past 18 years, helping customers to present their product realistically out of the CAD drawing. With the quantity of over 20 high precision CNC machines and the maximum capable size of 1.8m*0.8m*0.6m, we can meet the demand of any CNC metal prototype in 7 working days and help them to quickly verify the product precision in terms of the material, dimension, color.

Why choose us? Hongkong Bordersun customize plan and specification for each project, strictly control the manufacturing process, make examination and test before stepping into next process to prevent the NG product flow into next process. A project engineer will be assigned to follow each project to ensure the quality and progress, guaranteeing the CNC metal prototype you receive is exactly what you want in dimension, assembling, and surface treatment, and to make sure you can get the prototype in time.